Gravity & Pressurized

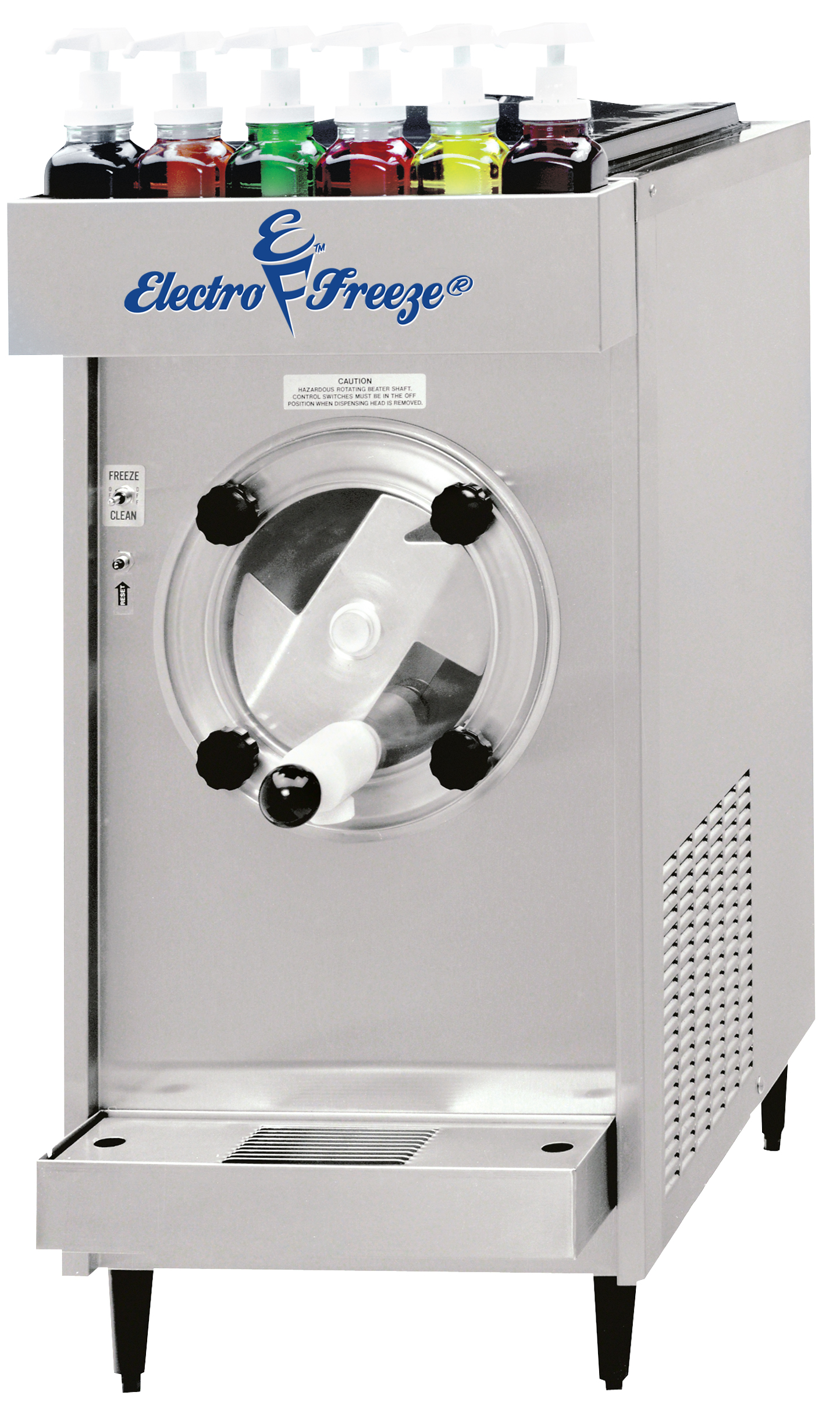

Gravity Soft Serve Freezers

Introduce a New Treat to Your Menu

The ElectroFreeze® gravity-based freezer design brings together exceptional craftsmanship & simplicity.

A gravity based system is a soft serve ice cream freezer designed to be filled and stored through the top of the freezer. While you fill the mix into the freezer, the mix will flow from the mix hopper down to the freezing cylinders. As gravity forces the mix down, it passes through a carburetor in which air mixed into the product. This allows for expansion of the product making for a airy treat. On a gravity based freezer your overrun can vary from 25%-45%. For example, the more overrun the fluffier the ice cream will be while the less overrun the more dense it will be.

The gravity-based freezer is a great entry level design for most operators while also having room to grow. The simplified design and usage of fewer parts compared to other gravity freezers make operating and cleaning quick and simple.

While these models generally have a smaller output, they still range from 150-450 4 oz cones per hour. Our gravity-based freezers have been very profitable for frozen yogurt shops, convenience stores, diners, burger restaurants, retirement villages, and more…

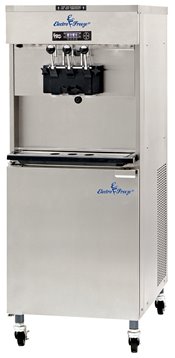

Pressurized Soft Serve Freezers

Take your Profits to the Next Level

The ElectroFreeze® pressurized freezer design upgrades the classic gravity-fed freezer for high capacity, so you can meet any demand with the best quality and consistency.

A pressurized based system is a soft serve ice cream freezer designed to be filled by a mix transfer system from the refrigerated cabinet below into the freezing cylinders above. The mix transfer system is designed with two pumps that draw from the mix containers that are stored in the cabinet. Once the pumps are turned on, they begin to draw the mix through the hoses into the freezing cylinders. As the mix passes through the pumps, the air hoses inject air into the mix. These air hoses can be modified by replacing the orifice at the end. There are many difference sizes that can range from 50-85% overrun, in some cases even higher. By increasing the overrun, you will increase yield without adding more mix; more profits.

In addition to the pump system, the pressurized freezers all come configured with a refrigerated cabinet. This cabinet ensures the mix stays at a consistent temperature throughout the entire mix, and it is equipped with a built in thermostat for easy tracking of food safety records. In addition to the containers, the larger pressurized freezers have a drawer assembly option to store over 20 gallons of mix. Although the cabinet is a great addition to the freezer design, there are some more parts to clean in comparison to the gravity freezer. While there are inherently more parts than gravity freezers, ElectroFreeze® pressurized freezers have less parts than other freezers which means quicker to clean, easier to operate, less replacement cost, which equals more profitability.